Basic program

STEP 1

Preparation

Prior to any work commencing Client will ensure that all access permits and necessary permissions have been secured.

STEP 2

Dig out pits

Client to dig out access points / pits on each of the pipelines prior to executing the program. Pit size is 15 x 6 feet. (4,5 m x 2 m).

STEP 3

Drain lines

Client will drain the lines of all water / fluid and test to ensure that there are no water / hydrocarbons / gasses / oil in the pipelines.

STEP 4

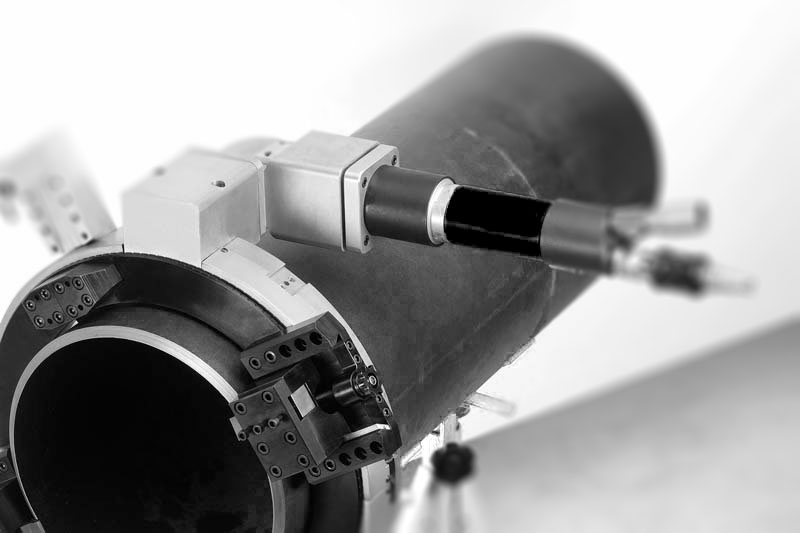

Mobilisation

The equipment will be brought on site and prepared before installation of liners.

STEP 5

CCTV

A CCTV will be run where possible.

STEP 6

Cleaning pit access

All pits must be properly drained and all valves removed. Cleaning access to the pipes is required to commence installation.

STEP 7

Pig

After valves are removed a foam pig will be propelled by water down the pipe bringing a small wire to connect the two winches for the calliper operation to verify the internal diameter of the pipeline.

STEP 8

Liners

The installation will commence by the liners being pulled-in with the winches.

STEP 9

Clean end

Once the liner has been pulled through, it will be cut to ensure a clean end - on which to attach the flange. The flanges will be connected with couplers.

STEP 10

Pressure test

A pressure test with water will be performed by client as the final approval of the newly installed pipe.

STEP 11

Valves

Upon completion of the installation and testing, Client will install new valves with the flanges and complete the commissioning of the pipelines.