RetroFit

Managing the life cycle of oil and gas pipelines with retrofit

ScanTech offers best in class on-site retrofitting of oil and gas pipelines which meets the continuously changing requirements, and ensures safe operation.

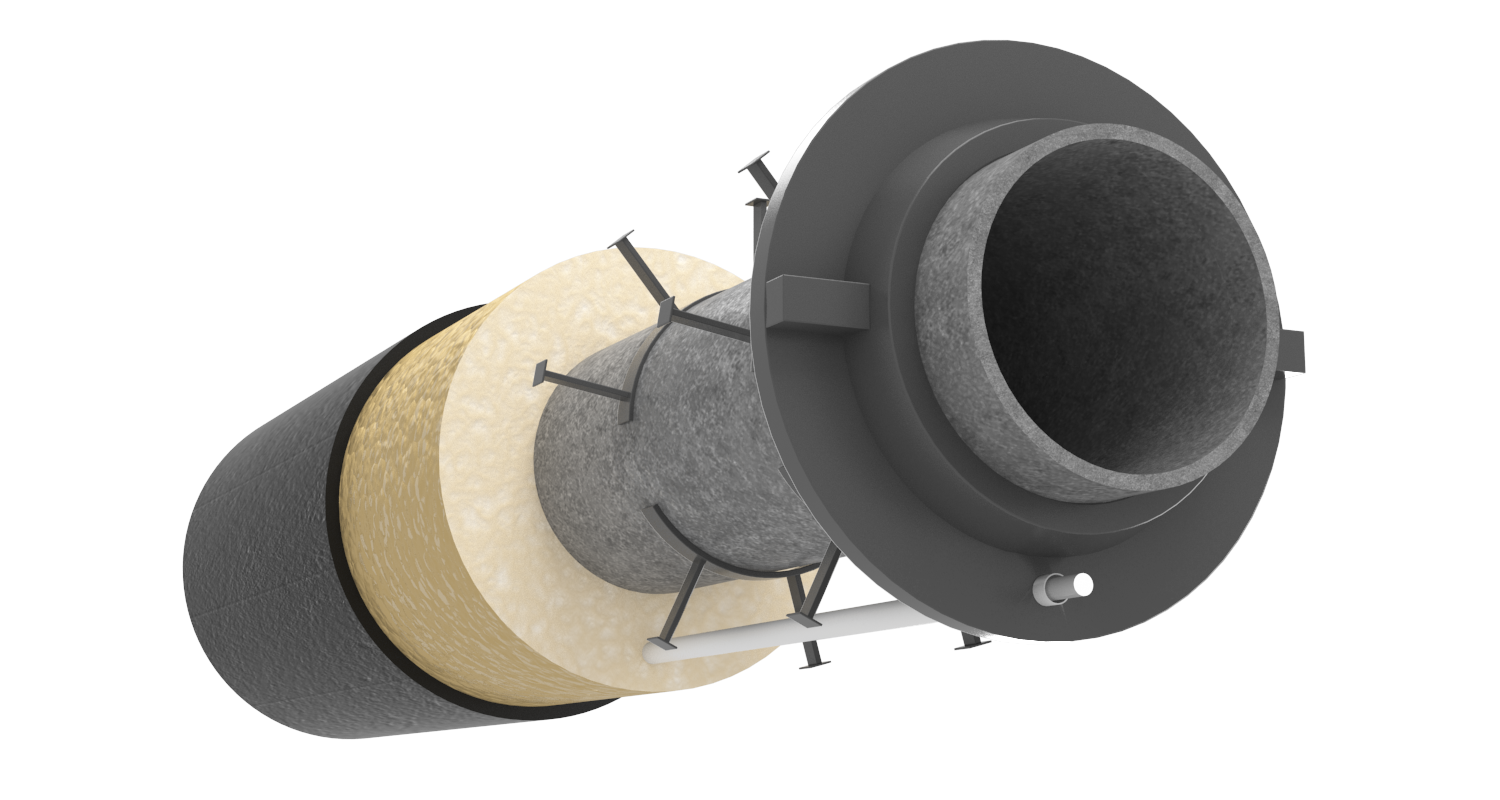

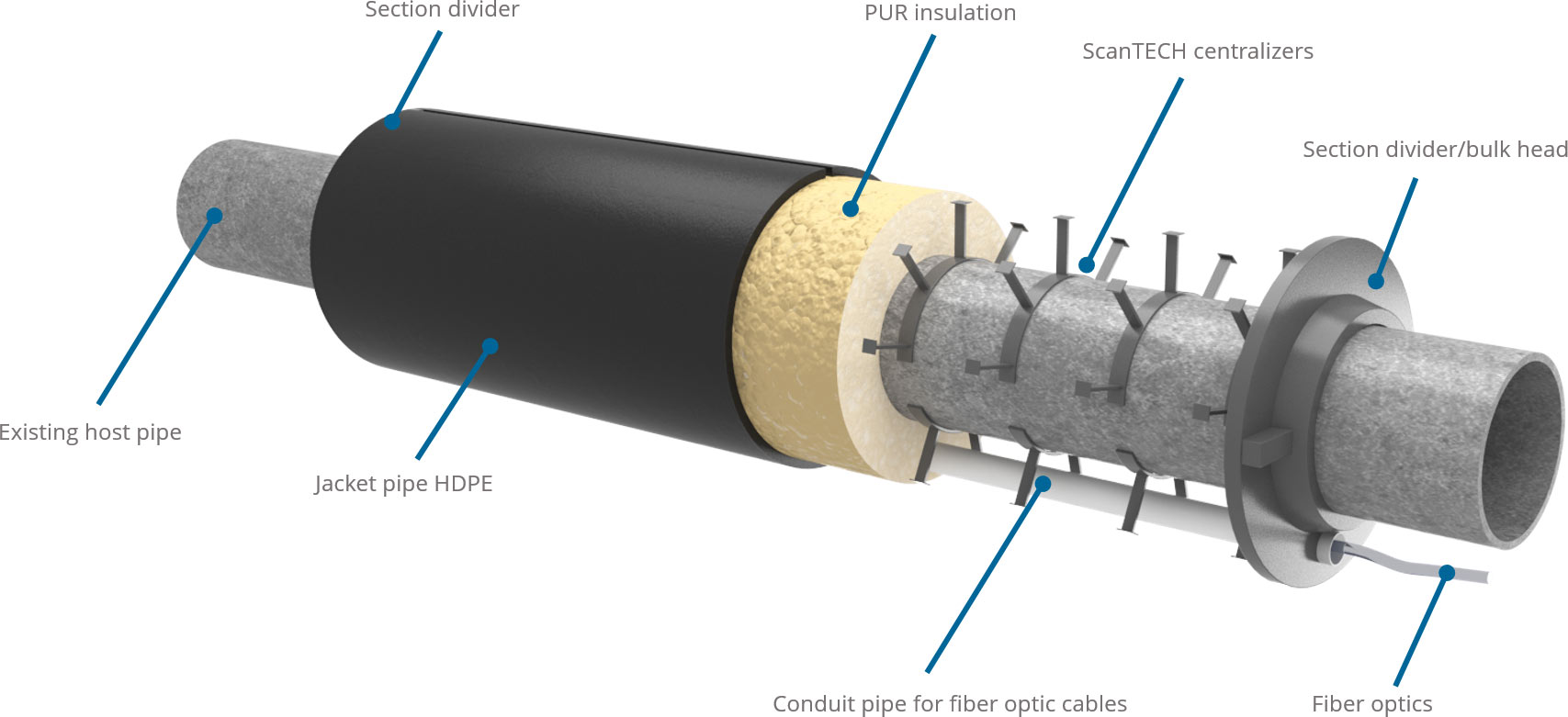

Based on the industry standards EN253 and EN489, our retrofit technology is the closest one can get to factory insulation with embedded state-of-the-art technology leak and 3rd party damage detection using fibre optic technology. Scantech is using ISO 14001 for factory made parts.

A supremely efficient layer of PUR insulation incorporates fibre optic cables that will give a warning to a control unit and the hard and sturdy HDPE casing will then contain leaks in 6 meter sections thanks to the patent pending design. This giving operators time to react.

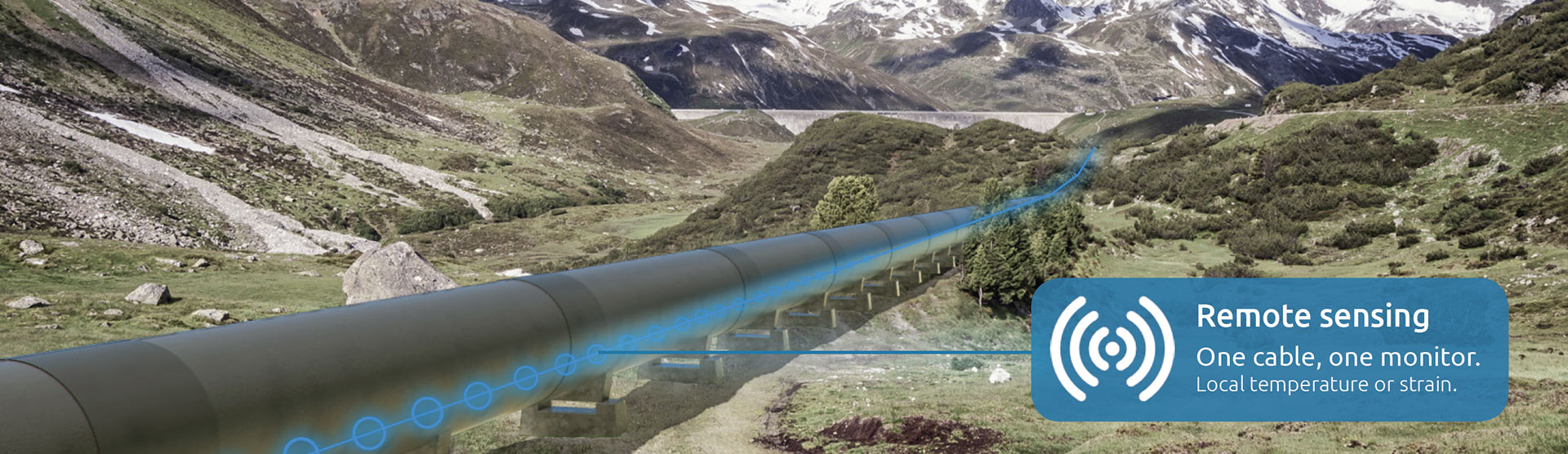

Keep your system under continuous supervision

Wouldn’t it be perfect to have a detection system to monitor your entire system of pipelines?

Benefits

Benefits:

Principles of retrofit

Improve lifetime performance of your pipeline

The pipeline operating company is required to monitor mechanical loads, pressure changes, corrosion rates etc. to evaluate the risk of pipeline leaks. Thus, the pipelines must be perfectly designed to meet these challenging operating conditions.

Therefore, oil and gas pipelines require continouos monitoring during their operational life. In the event of imminent failure, the operator has to identify the critical component and its exact location before a minor spill turns into a major disaster.

On site thermal and fibre optics cables

Combines key benefits from four technologies

Our business partners delivers high quality and state of the art solutions. Constant real-life, pin point accuracy and as a bonus 3rd party damage alerts.

“This system can save the world from another environmental disaster”

Technical information

How des RetroFit work?

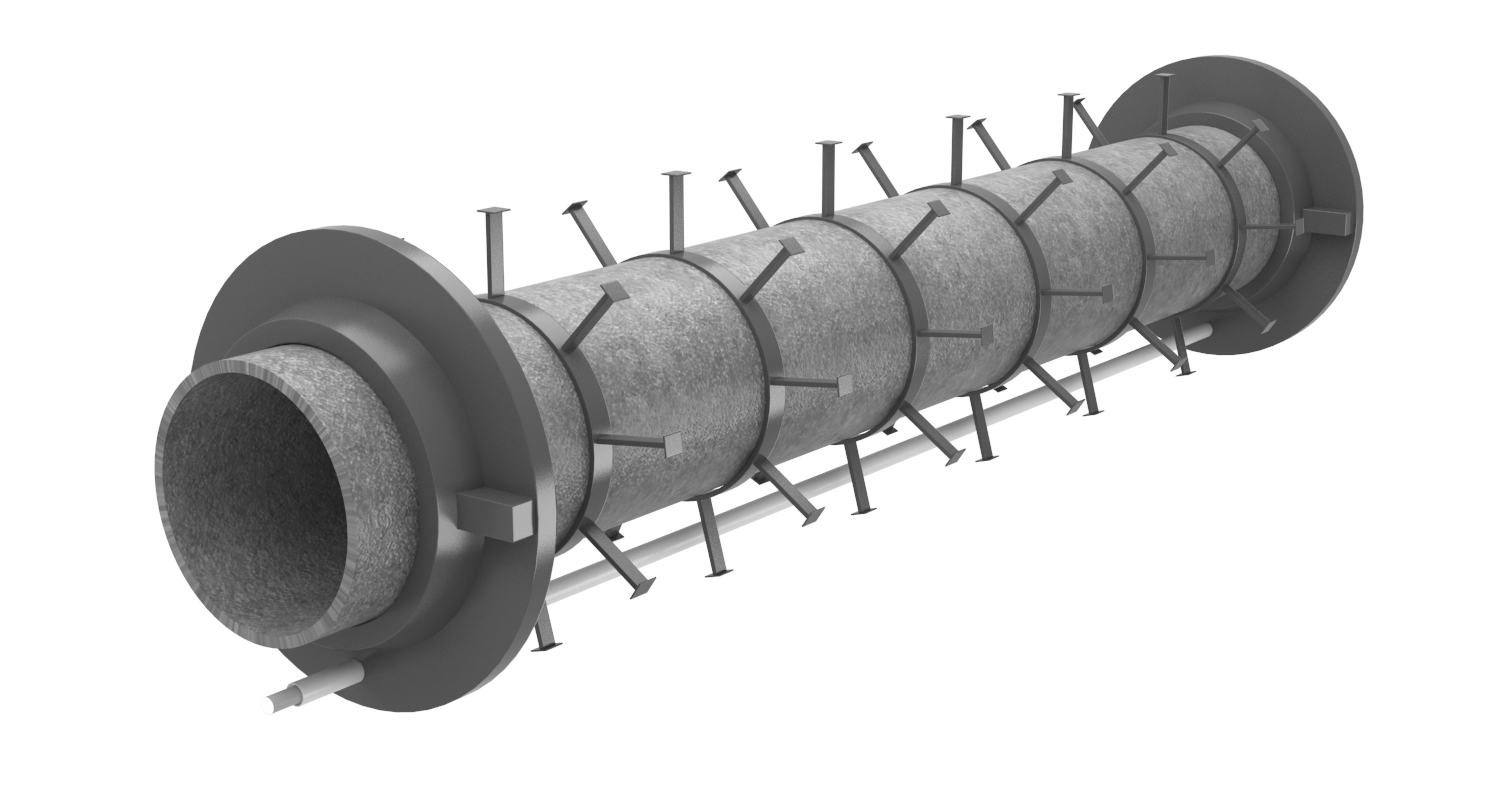

Hostpipe section with spacers, fiberoptic cable and endseals installed. Ready for jacket.

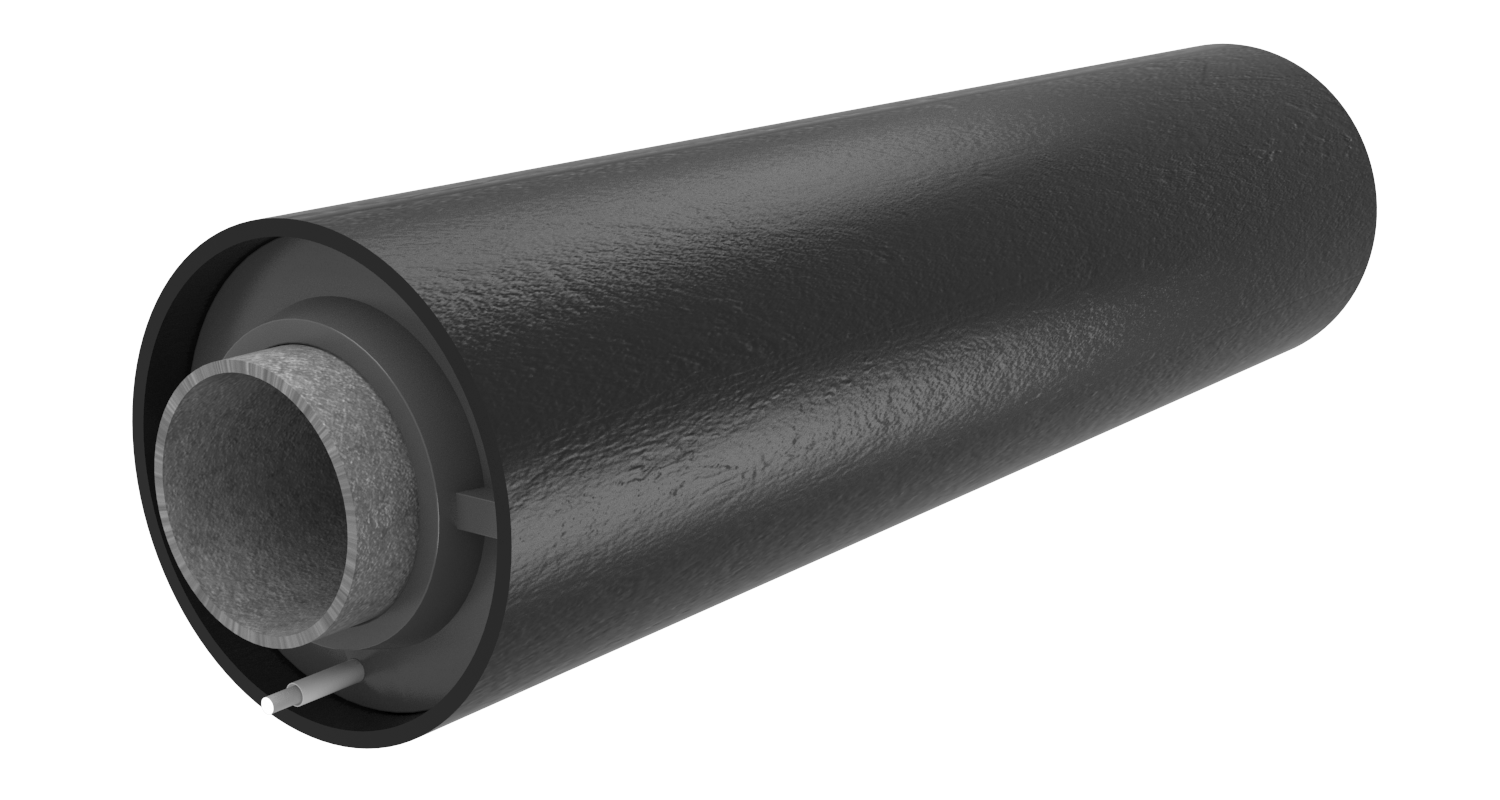

Jacket installed. Ready for PUR.

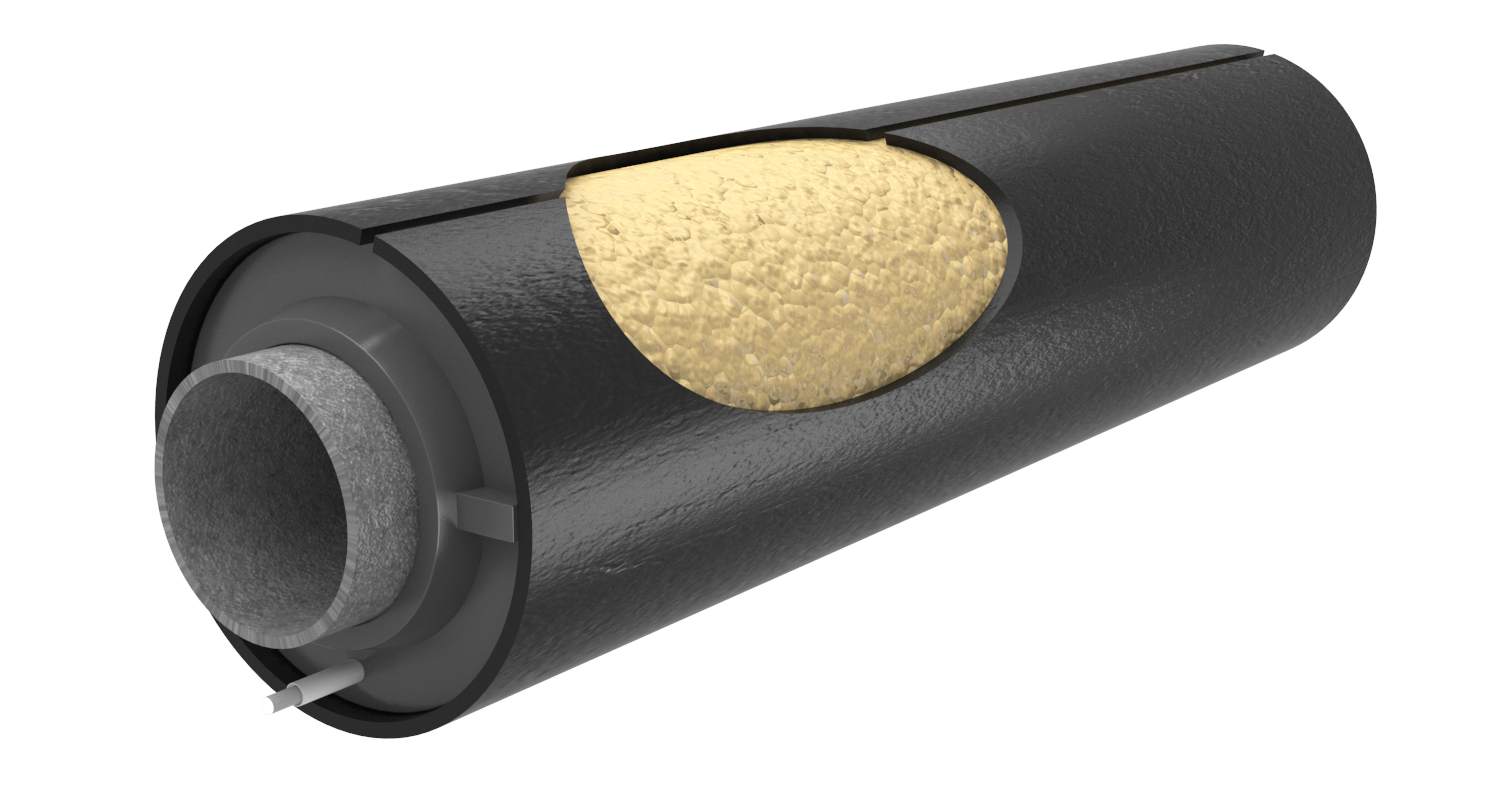

On-site PUR foam installation according to industry standard.

Recent development

Our value proposition - definitely a cost effective alternative to replacing your pipeline.

Our retrofitting solution provides a solution that will reduce the OPEX and therefore pay for itself within few years after installation, both for oil and gas pipelines. ScanTECH’s on-site retrofitting principles with injected PUR insulation and the protective casing in permeable HDPE, permits building 100% water tight series.

The insulation keeps the heated fluid efficiently, with low thermal losses along the whole run of the retrofitted pipeline.

With our state-of-the-art mobile equipment, a complete pipe run including bends, elbows, valves and more can be on-site retrofitted anywhere around the world.